High Dose Implant Strip (HDIS) – Challengeable process in semiconductor manufacturing

Photoresist strip after high dose implant strip remains one of the most demanding processes in

semiconductor industry. The challenge is to remove both the crust (or hardened layer formed during implant) and the soft bulk resist without burning the crust and therefore, without leaving carbonized residues which are very difficult to clean off. Controlled removal of hardened organic material and untouched resist at low temperature is key to cleanliness.

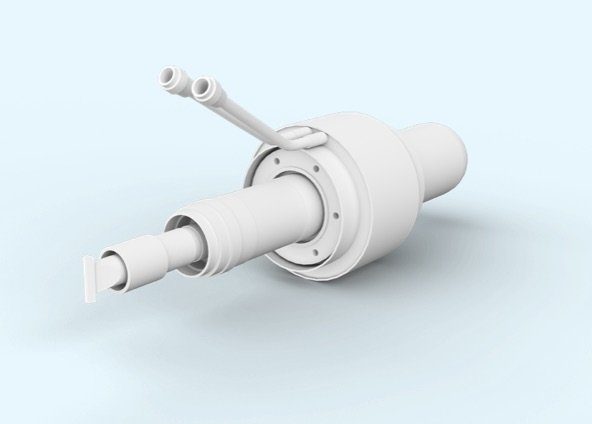

Microwave Plasma – Isotropic resist removal with least thermal load

Due to the nature of the RF-plasma, it exposes the substrate to a relative high intake of charged species (ions). These ions transfer kinetic energy when hitting the surface and cause the substrate to heat up. High temperature is very unfavorable to the post high dose implant strip as it will participate to further baking and hardening of the photoresist crust. Cooling of the substrate helps to prevent volume heating-up of the substrate but it cannot avoid local heating of the surface where the actual reaction takes place. Hence, even if the average temperature is kept low, the local temperature remains high

since the underlying reaction (ion-sputtering) is not affected by the cooling. Using Muegge’s microwave assisted plasma systems, the energy transfer is extremely low, no charged particles are formed which could be released into the process chamber. As a result the substrate remains cold, the only heat-source it is the chemical reaction of the exothermic photoresist removal. As the reaction heat is a direct result of the resist-strip process, it can be easily controlled by the process conditions.

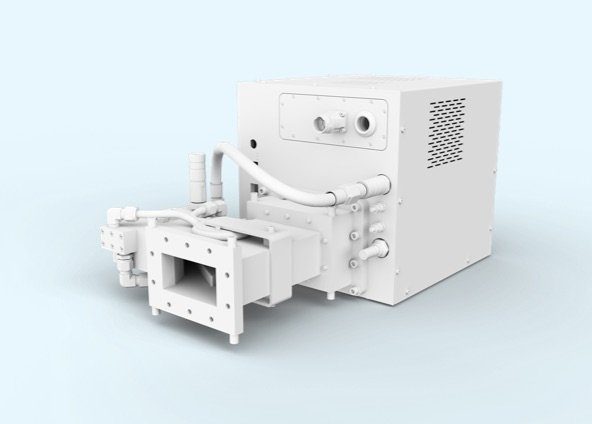

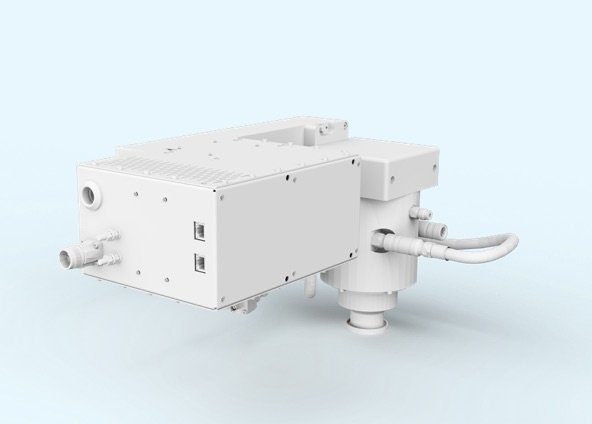

MUEGGE’s solution – accurate, reliable and repeatable

Microwave assisted plasma efficiently uses the energy to form highly reactive, neutral particles called radicals. No ions are formed which are the carriers of kinetic energy, causing the substrate to heat up. Therefore the microwave-assisted remote plasma system is ideal for post high dose implant strip where temperature control is critical – no additional polymerization or carbonization occurs and the implanted photoresist can be removed smoothly.

The radicals released from the microwave assisted plasma guarantee a smooth, pure chemical removal of the damaged photoresist. As a consequence, the thermal load is extremely low which guarantees isotropic photoresist removal without further carbonization of the damaged photoresist.

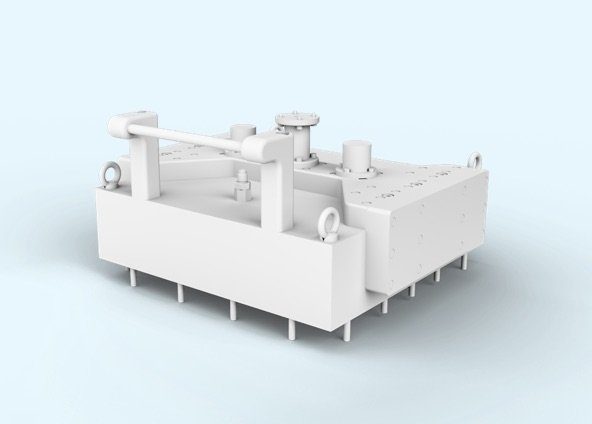

Microwave assisted plasma for flexible process control at low temperature

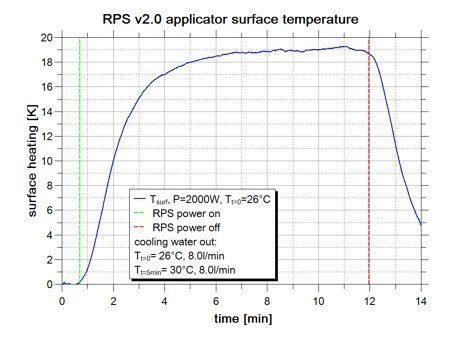

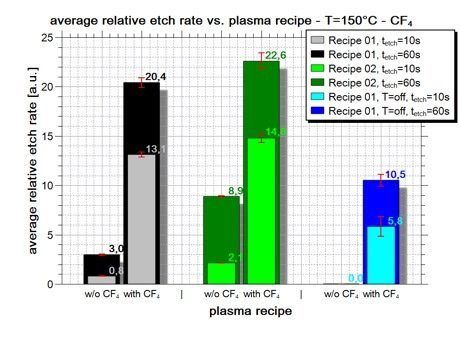

Radical-only formation results in little to no interaction with the surrounding surface of the plasma chamber, the temperature remains low (Figure 1). The pure chemical HDIS-process can be fine-tuned

for the three steps of the removal process:

- crust removal

- bulk ash

- Over-ash

No ions mean no need for additional cooling of the substrate.

Advantages of radical based post high dose implant strip

The three steps of high dose implant strip require appropriate flexibility to meet the different demands of each step (Figure 2). Microwave assisted plasma allows to cut through the crust, remove the bulk resist without blistering or resist burning and removed residues softly and with high selectivity during over-ash. Due to the physical properties, microwave assisted plasma is specially designed for fast but smooth ashing without attacking sensitive areas. The radicals generated in the plasma initiate the chemical reaction at the surface only. Without measurable electrical fields and ions present at substrate level, no plasma induced charging damage of critical structures occurs. Microwave assisted plasma is highly environmentally compliant due to nearly complete dissociation of process gases like CF4.