Customers interested in industrial microwave systems understandably need to know exactly how much energy they need for their specific application. Depending on whether it’s cooking processes, the temperature control of frozen products or the drying of materials – the energy requirement varies greatly depending on the material and application.

In this article we focus on a common application: the evaporation of water.

We have put together a summary of the general process and calculations needed to determine the amount of energy required to dry your material.

Microwave drying is faster and often more energy efficient than traditional methods such as kilns and convection ovens. Using the information in this article will help to determine the long-term operating costs associated with microwave energy drying.

What you can expect here

Energy estimation for drying materials with microwaves

Determination of the amount of water to be evaporated

Determining how your material reacts to microwaves

Calculation of the energy demand

Talk to us

Contact

1. Determination of the amount of water to be evaporated

For any given material, you must first determine how much water it contains before drying. You also need to set a target value for the water content after the drying process.

For example, if you have 100 kilograms of material with a water content of 60% that you need to bring to 10% saturation, the calculation is simple:

Amount of water to be evaporated [kg] = 100 kg *(0.6 – 0.1) = 50 kg

Generally, you also specify a drying time in which you want to expose the material to the microwaves to achieve this goal.

2. Determining how your material reacts to microwaves

Water is often the most microwave-active molecule in the base material and due to its high dielectric losses, it absorbs the main part of the energy coupled into. Therefore, the amount of energy lost by absorption to the rest of the material to be dried is minimized.

The following calculations refer to the amount of energy required to evaporate the water alone and should therefore serve as a rough estimate of the total energy you will need to use, as a small part of the energy is required to heat the rest of the material.

This loss is often low. However, for a base material with a high dielectric loss, the microwave absorption of the non-water content can become relevant. If you want to process such a material with microwave, you should allow for a longer drying time to avoid excessive heating of the base material.

3. Calculation of the energy demand

For an example calculation, let us assume that we want to evaporate 50 kg of water in one hour. Furthermore, we assume that the initial temperature of the material is room temperature, i.e., 20 °C.

The formula for calculating the amount of energy required to evaporate water is based on the specific heat capacity of water:

It takes 4.19 kilojoules (kJ) of energy to heat one kilogram of water by one degree Celsius.

Once this energy has heated the water to its boiling point (100 °C), another 2257 kJ are required to convert one kilogram of liquid water into steam.

The energy requirement calculation for our example (50 kg of water in one hour) results in the following:

Energy required to heat water to boiling point:

Energy_boiling point = 50 kg * 4.19 kJ/(kg*K)*(100 – 20)K = 16,760 kJ

Energy required for the evaporation of the water:

Energy_evaporation = 50 kg * 2,257 kJ / kg = 112,850 kJ

Therefore the total energy required for the evaporation of 50 kg of water is

Energy_total = Energy_boiling point + Energy_evaporation = 129,610 kJ

Since we want to apply this amount of energy within one hour (3,600 seconds) (remember: drying time should be one hour), the required power results from the energy demand and the desired drying time:

Power P = energy_total / drying time = 129,610 kJ / 3,600 s = 36 kW

4. Talk to us

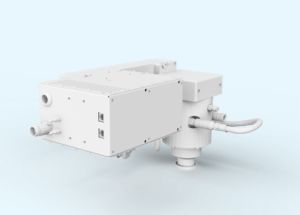

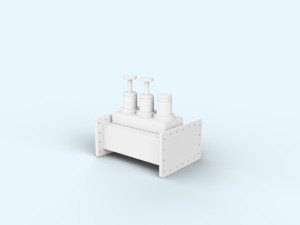

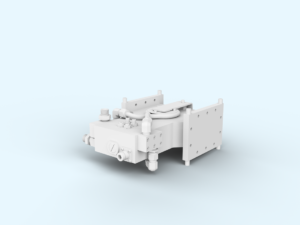

Consulting our technical sales department, these base data are a first point of reference for choosing the right microwave generator. In further discussions, our product managers will suggest additional parameters to get you enough power for your application.

In the example above, the required heating power can be supplied by a standard 50 kW generator. However, if the drying must be done in 30 minutes instead of one hour, two 50 kW generators would be required, or possibly one generator with 75 kW or 100 kW output power.

Go to our website for more information about microwave generators.

If you have any questions, please feel free to call or send an email.

5. Contact

MUEGGE GERMANY Reichelsheim, Germany | MUEGGE GERLING Modesto, CA 95351, USA |