Chamber-Clean after Dielectrics Deposition – A case for isotropic microwave plasma

As deposition is one of the pillars of semiconductor production, it depends on a controlled, repeatable and clean environment. One challenge of the deposition process is, that deposition does not only occur on the substrate but also on the chamber walls. This is a permanent threat of particles and contamination. Hence, the complete and repeatable cleaning of the process-chamber is key for layer quality as critical dimensions keep challenging physical limits.

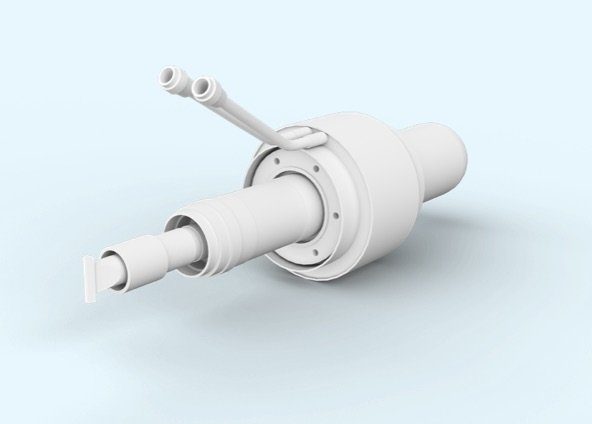

Microwave plasma is the perfect solution for removing such thick coating off the chamber walls. The advantage of microwave (MW) plasma over RF-plasma makes the difference – chamber walls can be cleaned even without direct expose to the plasma source due to its unique property of microwave.

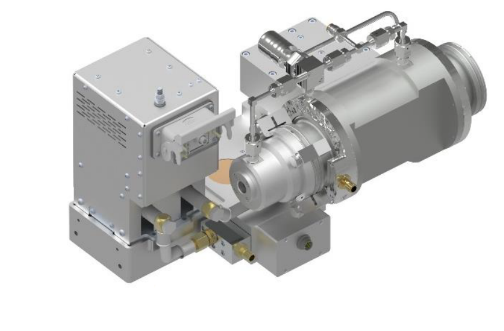

Microwave Plasma – Isotropic and fast clean

When it comes to chamber clean, RF-plasma is not ideal due to its anisotropic properties. As ion bombardment is inherent to RF-plasma, it required direct exposure of the parts to be cleaned. In reality, parts of the chamber walls are hidden to the plasma source which causes incomplete clean and subsequent flaking, particles and low yield. Microwave assisted plasma clean is the solution to this problem. The generated radicals reach hidden and protected areas of the chambers which are invisible to the RF-source.

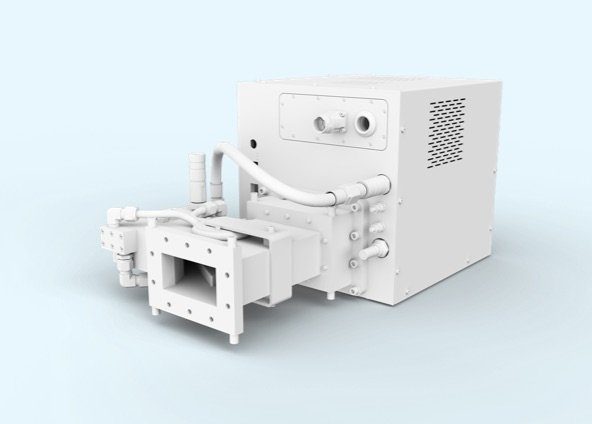

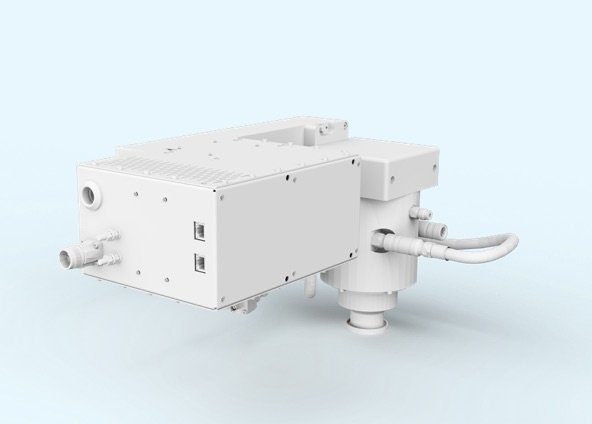

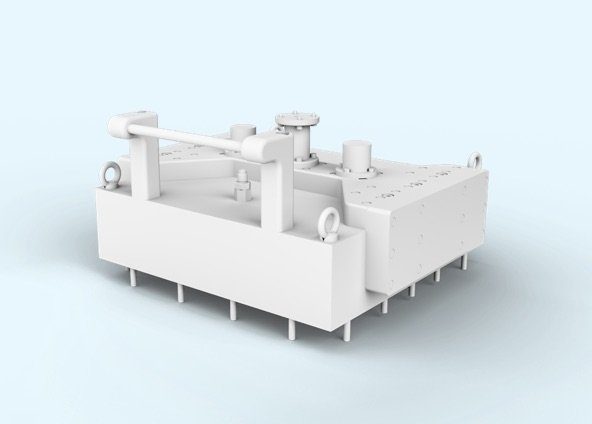

Muegge remote microwave-plasma addresses these issues

- The radicals generated in the applicator reach the chamber and will do the cleaning, even if there is no direct exposure to the source. No more incomplete cleaning, the radicals reach every corner of your chamber.

- Exposed areas cleaning first remain safe from further attack – unlike RF plasma where sputtering can alter or damage the side-walls.

- Over-etch is safe to perform due to the chemical nature of the cleaning. No ion-bombardment causing damage to clean parts of the chamber and sensitive equipment (e.g. e-chuck).

- Muegge’s solution for chamber clean is sustainable and energy efficient. All energy is transferred into the formation of radicals with extremely low thermal load.

Wide process range

The Muegge remote plasma clean is available for all materials which do not require corrosive chemistry, e.g.:

- Silicon dioxide

- Silicon nitride

- Low k materials

- Organic materials